Introduction

With the continuous development of the social economy, the industrial development momentum is very rapid. Still, due to factors, the current lower level of mining and the supply of mineral products is in short supply. Many underground mining equipment manufacturers have begun to conduct more research and production of underground mining machines. Hence, the underground jumbo drill was born. An underground Jumbo drill is mainly composed of rock drill drill arm frame of steel structure. This runs mechanism and other necessary auxiliary equipment. Adding underground mining equipment can successfully increase underground mine output by the needs of underground mining. The following post will explain how jumbo drills work in underground mines.

Drilling underground mine deposit

Though ore deposits and ore bodies existed. But underground mines need to choose different ore deposit development methods to ventilate efficiently and drainage. This is the advance of personal mining safety. One or several underground drilling machines have a unique drill arm or drill frame and an automatic propeller. It equips with a traveling mechanism to realize the mechanization of the development of ore deposits.

Underground mine improves into a good and more prominent space to facilitate underground mining. The stable and prosperous deposit development is of great significance for the next underground mining. At this time, we need a powerful underground large-scale jumbo drill to help us realize these problems of underground mining. So, the underground jumbo drill made of Fucheng Underground Mining Manufacturer from China is mainly used for drilling and other industries about undreground mining.

Drilling underground mine roadway

Underground mining block work refers to predetermined plans and drawings to drill a series of roadways to create the necessary conditions for cutting and mining block work in underground mines. Therefore, this work is of great vital for underground mines, which not only require absolute safety of underground mines, but also require underground mining equipment that can dig tunnels efficiently. There are thrusters on an underground jumbo drill, which functions as the rock drill that can quickly drive to the working face and give the rock jumbo drill a specific axial thrust drilling when preparing to open a hole. The operation of the thrusters shall be reversible.

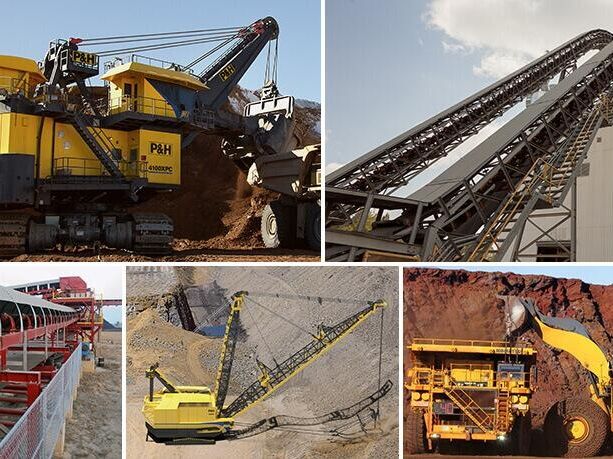

The shaft thrust and thrust speed generated by the thrusters should be adjusted arbitrarily so that the rock jumbo drill can work under the optimum shaft thrust state. At the begining of the underground mining is to drill a large cavern in the underground mine. Underground jumbo drill can hole and clean the tunnels. Meanwhile, jumbo drill usually uses many different underground mining drilling techniques. For example, Fucheng‘s underground jumbo drilling rig has a borehole diameter of 3.3 to 10.2 cm and 270 cm, and this underground jumbo drill mining method is suitable for all underground drilling projects. Underground Jumbo drill is lasting and used . Most mining machines generally consist of one to three rock drills or more. Underground mining operators stand on cranes, load explosives into the holes and clear the tunnel face.

Cutting underground mine deposit

Jumbo drilling rigs have opened up free ground and extremely high underground in underground mines, creating fit and complete working conditions for mining blocks. Such conditions can provide workers with a safe and efficient working space in underground mines. However, Underground Scaling Jumbo is made in China Fucheng, which is specifically used to mine the exceedingly high space of underground mine machine, which professionally coordinates with underground jumbo drill work. In addition, in order to adjust all kinds of the needs of the mining, underground jumbo drill also has a new direction towards the direction of large-scale or small-scale development. The primary components of an underground jumbo drill of major companies in the world, such as drill booms, thrusters, and control systems, will have been standardized and serialized.

Wide range of applications, high universal rate of parts. It can be assembled into various types of underground jumbo drills according to the different requirements of customers, which finishes the diversification of varieties, shortens the product design cycle, and enables rapid product replacement. Just only not, Fucheng also manufacte specialize underground mining transport machinary, such as Underground Scaling Jumbo, Underground Mining Scooptram, Underground Mining Trucks, etc. Fucheng has been producing underground mining equipment for nearly 2 years and is a fairly reliable supplier in China.

Transport ore drilled in underground mine

The core of underground mining underground ore is transportation of underground ore from underground mines. And the ore block is the core of the underground mine. Most producing ore involves three operations. The first is the operation of taking out the ore with suitable size from the underground mine ore body; secondly, the ore lead-in, which means transport the ore from the falling surface to the conveying level; finally, the ground pressure management, including filling and various supports maintain.

For the above-mentioned three steps, you can do these operation efficiently, if you use the underground mining equipment of Fucheng.At the same time, the underground mining jumbo drill has strong supporting force, which provides safety guarantee for underground mining operators. This advantage makes ore extraction in underground mines smoother and safer. Besides, our underground mining mechine manufacturer, Fucheng from China, also sells another underground mining equipment about speclize undergrounder metal mine. For example, gold mine underground mining equipment, copper mine underground mining machine, iron mine underground mining equipment, etc. Buy it now!

Conclusion

With the development of technology and automation technology and its application in an underground jumbo drill, the jumbo drill shows a trend from mechanization to environmental automation, diversification, and protection. In order to better promote the underground mining project and get rid of the existing difficulties, our China Fucheng underground mining equipment manufacturer will continue to research and innovate mining equipment, and sell various underground mining equipment in large quantities. whose most powerful advantage is that it has a professional and reliable technical research and development team, which can better correctly design and produce underground mining machinary according to the requests of customers,and offer one-step service after sale.