Underground mining can be referred to as extracting minerals and ores from below the earth’s surface. And the machine you use for this purpose is the underground mining loader.

So, are you an individual who knows the machine by name but lacks in-depth information? If yes, look no further as you have already landed on the right page. We have formed this guide for you containing all the essential knowledge you must know to reap maximum benefits from the machine. So, without wasting further time in the discussion, let us directly jump into the content. Please have a look.

All you need to know about underground mining loader:

Below, we will discuss information about underground mining loaders by dividing them into different categories to ensure a better understanding. So, stay tuned till the end

What is an underground mining loader?

An underground mining loader is a machine you use to transport minerals and other extracted ores and rock waste. Also, it is used for evening out the ground and discharging slag and ore at the stop. You can also upload it on the lower chute, higher transport vehicle, or mining cart.

In addition, contractors use this machine to pave roads, clean the sites, and repair bucket roads. The lhd loader has many advantages that you will get to learn as the article moves along.

Advantages of underground mining loader

Enhanced efficiency and effectiveness

According to researchers and observations, mining loaders increased the productivity and efficiency of mining operations by up to 50 percent, higher than the efficiency of electric racks and diesel scrapers.

The underground lhd loader can accelerate the mine developments when talking about construction operations, speeding up the whole process.

The improved working condition of the drivers

Using advanced electronic technology, these mining loaders make the driver’s operations more convenient, comfortable, and safer.

These lhd loaders allow individuals to realize the environmental and socioeconomic benefits of the equipment without sacrificing productivity and effectiveness.

Cost-efficient

Underground loaders substitute the workforce with technology. For instance, if an individual does not own a lhd loader and higher labor for the same purpose, they must pay each of the laborers monthly. Hence, it can help save a lot of money in the long run.

However, purchasing a loader is a one-time expense and will not require monthly payments. Or weekly salaries and wages, except for regular maintenance costs.

Components of the LHD underground mining loader

Three significant components are combined to form the underground mining loader: Engine, Torque, and the Great box. We will discuss each of the components one by one. Please look below

1. Engine: The engine is one of the most critical parts of the loader that acts as its core. The same is why the loader must obtain a solid and efficient machine.

2. Torque: torque contains three pumps: the working, steering, and pump. The operational pump supplies lift and dump pressure oil. The steering pump supplies steering oil, whereas the third and the last pump are responsible for changing speed.

3. The great box: the great box is integrated and split.

How to choose the LHD underground mining loader?

There are various types of underground loaders available in the market to choose from. Yet you must know the correct way of its usage to minimize the chance of losses. Hence, one must conduct proper research and learn about LHD underground mining equipment characteristics before purchasing a piece. The same is why we are presenting three points over here that you can put under consideration for your help.

- Choose an underground LHD mining equipment that obtains a diesel engine; we are saying this because loaders with diesel engines are less expensive to operate and will last for decades.

- Choose the loader that has multiple ties and snow chains. In addition, go for hydraulic-mechanical transmission.

- You must consider the braking performance of the LHD underground mining loader, including parking braking, multiple braking, and emergency braking. Remember, there are types of brakes: caliper disc type, shoe type, and wet multi-disc type.

How to increase the use life of the underground mining loader

Below, we mention some information to use the equipment correctly and improve its life. So please read carefully.

Read the given instructional manual.

The first and foremost thing you must do to use the underground LHD machines correctly is read the instructional manual that comes with the machine.

It primarily contains instructions and all essential guidelines to enable the operator to operate the underground mining machine correctly.

Control the working hours

It is recommended not to use the LHD machines if you notice any flaws in its performance. Also, one should control the equipment’s workload within half of the rated workload.

Check your underground mining loader daily.

You must not skip checking your underground loader machine every day. So, after each work day, make sure to clean up the underground loader LHD machines solely. After you are done with cleaning, check for any loose parts and tighten them.

Trust us, pulling loose parts as soon as they are found helps prevent minor problems and increases your loader’s life to a certain extent.

Refill oil on time

Check daily for the hydraulic oil, fuel oil, lubricating oil, coolant, and brake fluid before operating the LHD underground mining loader. And quickly replenish if you find a lack of any of this oil.

Remember that it is essential to maintain the underground mining loader after the break-in period has passed.

Here is the summary of how you use the underground loader equipment:

- Make the operator read the full instructional manual.

- Check for problems in the loader every day. If found any, get it fixed as soon as possible.

- Make sure to keep the fuel and oils sufficient

- Maintain the loader every day

Top underground loaders

Now that you know all the essentials about underground mining loaders, we present a list of 5 top underground loaders and their specifications.

Caterpillar R3000H

The caterpillar R3000H is one of the most famous loaders you can find in the market. The LHD machines are an all-rounder that can handle everything from truck loading to material handling.

The equipment can load 20,000 kilograms or 44,000 pounds and operates at the power of approximately 305 watts.

Diesel Scooptram FCYJ-0.6D

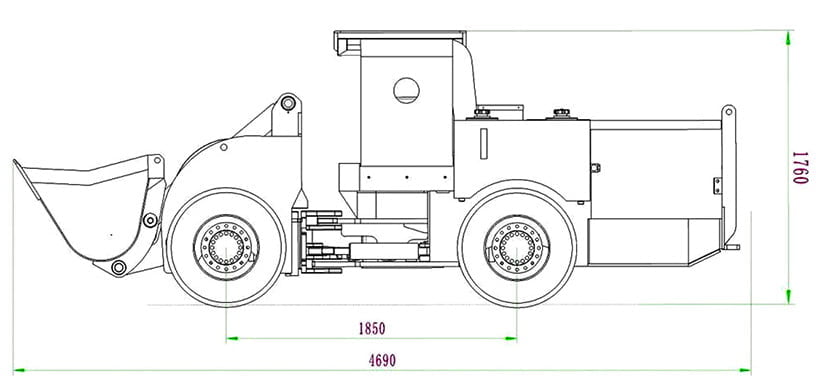

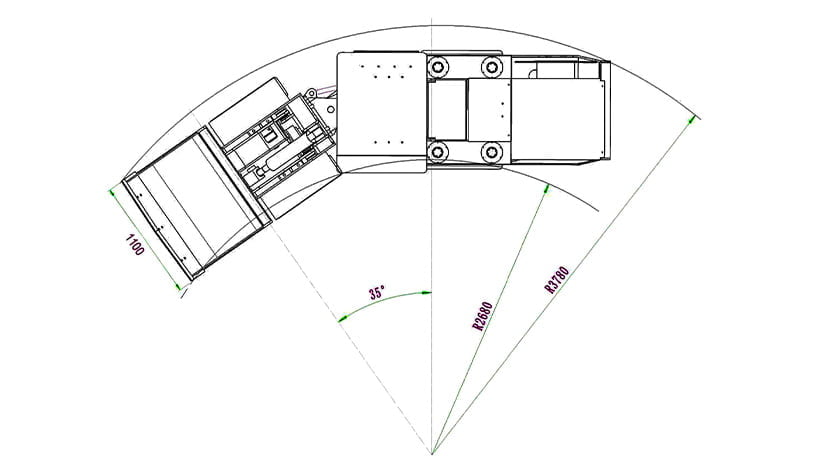

This LHD machines have dimensions of 4690:1100: 1760 mm, a bucket volume of 0.6m3, and a rated capacity of 1200 KG. The same is why this underground mining loader provides the operator with easy operations that ensure safe working.

Along with safety, this equipment is excellent in terms of reliability. That means the rugged frame of the LHD underground loader equipment is built to endure the surrounding stress and tramming cycles.

Diesel Scoptram FCYJ-3D

The brand is Germany-based and is known for providing efficient and robust engines for underground mining loaders. The bucket volume of Diesel Scooptram FCYJ-3D is 3 m3, and the rated capacity is 6 tons. In addition, the LHD machines are equipped with a powerful engine from a renowned and well-reputed brand: DEUTZ.

Also, the LHD machines have ample and comfortable cabin space for the operator and a smoke purifier that purifies all the smoke before it is discharged.

Hence, with all of the features mentioned above, the loader is one of the top picks in the market today. The features help the loader provide an uninterrupted loading cycle and smooth experience, guaranteeing the savage of your money and time.

Epioric Scooptram EST2D

The Epioric Scooptram EST2D is another renowned loader with a trimming capacity of 36000 KG/ 7937 pounds. Also, it can adapt to an extensive range of frequencies and configure multiple cables.

This LHD underground mining machine maintains a comfortable and quiet cabin for the operator with handly access to all the controls. The compact design is convenient and perfect for smaller operations within the small and narrow mines where other underground mining loaders would struggle even to fit.

Diesel scooptram FCYJ-4D

Last but not least, Diesel Scooptram FCYJ-4D is next on the list. This loader also obtains the DEUTZ’s engine supplied from Germany and a purification device made in Canada.

The machine is known for its comfortable experience and excellent performance. The front frame connection and rear frame are articulated well, which is nothing else but a plus point.

Conclusion

On the bottom line, an underground mining loader is a machine that helps transport minerals and ores from small and narrow mines. There are various benefits that the loader provides to the individual. For instance, it enables you to save money, enhance performance, and go on.

However, one must know some essential tips for efficient usage mentioned in the above content. Also, you will find a list of some top underground loaders in the article. So make sure to read the whole range very carefully. Rest, we wish you the best of luck.