How does a hydraulic pump work?

A hydraulic pump is a device that creates hydraulic energy from mechanical energy. Hydraulic pumps are integral to hydraulic systems. They transmit or amplify energy using pressurized liquids. A hydraulic system can execute different tasks including lifting and carrying heavy loads.

The use of hydraulic systems can be traced back to the Egyptian and Mesopotamian periods. Water-based hydraulic systems were used for irrigation during these periods.

How do Hydraulic Pumps Work?

Pumps are key components responsible for the efficient working of a hydraulic system. A pump, fluid receptacle, and a network of valves and tubes are key components of a typical hydraulic system. While the pump builds fluid pressure, valves and tubes work to regulate fluid flow.

Within a hydraulic system, hydraulic pumps generate energy referred to as hydraulic power. This hydraulic force can be flow or pressure. Pumps act on the mechanical energy created by a pressurized hydraulic fluid to create hydraulic power. Oil and water are the most common hydraulic fluids used in hydraulic systems.

The function of a pump within a hydraulic system remains constant though the application of the system may vary.

A pump essentially performs the following functions:

- Pressurizes the hydraulic fluid. This pressure generates flow, moving the liquid through the hydraulic system.

- Sets into motion subsequent actions. The pressurized fluid moves through valves and tubes at a set flow speed. Valves and tubes direct the fluid to required mechanical devices like motors and cylinders. This pressurized flow works to actuate these devices.

- Activates fluid flow, which in turn exerts a force on motors, cylinders, or other connected devices. This force on the devices fulfills actions such as load-lifting, or movement of metal components from one point to another.

- Starts the pressure-generating cycle according to preset time intervals. When the hydraulic fluid returns to the receptacle, it undergoes cooling. It stays inactive till the pump starts its iterative functions.

High-pressure environments such as underground mining demand high-performing pumps in hydraulic systems. Fucheng hydraulic equipment comes with an ISO9001 quality certification and a CE certificate. These pumps are known for their longer operating life and exceptional volumetric efficiency.

Working Principle of Pumps in Hydraulic Systems

The function of a pump in a hydraulic system is to generate flowing power for the hydraulic liquid. The principle behind the functioning of a pump is that a liquid is almost incompressible. This means a liquid’s volume cannot be compressed completely. So, when a pump compresses the hydraulic liquid, the result is the generation of a large force with negligible loss of pressure.

This principle makes hydraulic pumps invaluable in commercial settings. Pumps can generate huge quantities of force at less pressure over larger distances. This makes them highly efficient in lifting and displacing heavy loads.

The working principle of hydraulic pumps is simple yet powerful. This principle enables the machines to not only create force but also multiply it by many folds. For example, a small hydraulic motion can produce the force essential to move a large load.

Types of Pumps Used in Hydraulic Systems

Pumps in a hydraulic system differ in the components they use to build force and move fluid. Given here are some widely used pumps for hydraulic underground mining applications:

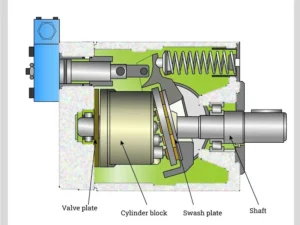

- Piston Pump– This is a reciprocating pump that employs a piston to generate fluid flow. This pump is efficient for high-pressure applications. In underground mining, structures supporting roofs need a high-pressure operation. This is best delivered by piston pumps.

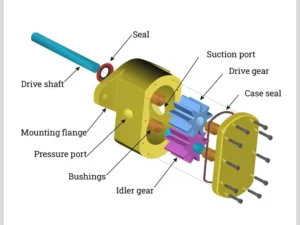

- Gear Pump –This pump generates fluid pressure using gears. A pair of meshing gears rotate to propel the hydraulic fluid forward. These pumps are low-maintenance as moving components in the design are very less.

- Lobe Pump – This pump uses two or more lobes and their rotative motion to move fluid.

- Vane Pump– This pump uses vanes set on a rotor for fluid transmission. A vane pump delivers a stable fluid flow across a range of pressure values.

- Screw Pump– This pump relies on a set of interlocked screws to pressurize fluid and move it forward. The flow of the fluid is in the direction of the axis of the screws. Being self-priming, these pumps do not need manual intervention to pump liquid into the pump. The machine draws the liquid by itself.

- Hydraulic Ram Pump– This pump uses incoming water itself to displace water from its original position to an elevated destination. This pump works on the “water hammer” concept. Here, the energy of incoming water is used to build its pressure and move the liquid to an elevated delivery line.

- Electric Hydraulic Pump– This pump uses an electric motor to generate hydraulic force. This pump enables efficient operation in applications involving remote and point-to-point locations. These pumps generate power for material-handling equipment in underground mining projects.

Why Use Hydraulics Pumps?

Environments such as underground mining are demanding and risky. Hydraulic equipment such as pumps deliver unparalleled value in such environments. Hydraulic systems simplify a range of laborious tasks such as moving dirt and penetrating rocky surfaces.

Some compelling reasons that make hydraulic systems indispensable for certain industrial environments, including underground mining, include:

Outstanding Task Efficiency

Pumps in hydraulic systems come with a high power-to-weight value. As a result, they generate and displace enormous force using only small working components. They are ideal for applications where weight is a key safety factor. Vehicles used in underground mining can benefit from such hydraulic equipment.

The fluid force that a pump generates is transmitted again and again to different required parts within a hydraulic system. This function makes pumps one of the best equipment for handling repetitive tasks.

Drilling rocks and moving earth are repetitive, laborious, and time-consuming in underground mining. Using pumps delivers high performance constantly, in such environments.

Low on Maintenance

Pumps do not require extensive maintenance as they contain only a few moving parts. They require less lubrication and part replacement compared to mechanical or electrical systems.

High Level of Safety

Environments such as underground mining pose a high risk as they can be explosive. Sparks from electrical systems present high levels of danger. Hydraulics equipment presents a safer and more efficient solution for these conditions. Pumps make several tasks, including material handling and actuating components easy and fast.

Conclusion

Safety and high performance are primary for companies working in high-risk environments. Hydraulic equipment offers safety, high efficiency, and faster turnaround.

Hydraulic equipment from Jinan Fucheng offers quality, efficiency, and safety. The company specializes in underground mining equipment. It has over 20 years of experience in manufacturing, trading, and maintenance of hydraulic equipment.

If you want to know more about hydraulic equipment from Jinan Fucheng, click here.