Introduction

The mining industry is the economic pillar of global development, and both China and the United States are world mining powers. The technological progress of the mining industry mainly depends on the development of mining equipment. The production technology level of mining equipment manufacturers USA is first-class in the world. The development of mining equipment manufacturers in china is late, but through the introduction of foreign advanced technology, mining equipment has also been greatly developed. In this article, we compare mining equipment manufacturers in china and mining equipment manufacturers USA from several different aspects.

China

Price

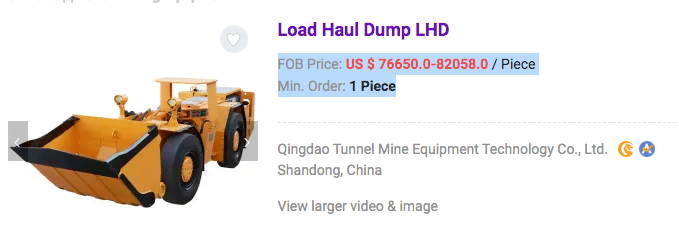

Take the following product examples:

Generally speaking, the price of mining equipment needs to be analyzed in detail, but the market price is generally tens of thousands to hundreds of thousands of yuan. This needs to be based on the specific model to have a specific quotation.

For now, the biggest advantage of mining equipment manufacturers in china lies in the price. As the demographic dividend is gradually disappearing, the price advantage is disappearing. Southeast Asian countries have a huge labor force and are gradually succeeding in China. Where should mining equipment manufacturers in china go? We need to act decisively.

Current status of mining equipments

Since the founding of New China, we have implemented several five-year plans. Among them, the introduction of mining equipment technology has enabled my country’s mining equipment to develop greatly, with a certain scale and standard. Up to now, mining equipment manufacturers in china have been able to manufacture all kinds of mining equipment.

- Open-pit mine

From the perspective of equipment level, my country’s open-pit mine equipment can be roughly divided into three categories:

- Small-scale mines have single equipment and no matching equipment, and some procedures have been manual labor.

- The level of mechanization of medium-sized and some large-scale mines is relatively high, but the equipment is relatively backward and the efficiency is not high.

- A few large-scale mines use imported modern equipment, which is more efficient.

- Underground mine

- Drilling equipment: DTH drill stands are still commonly used in mines. High-efficiency hydraulic rock drills widely used abroad have not been widely promoted in China. Imported hydraulic mining is used in a few domestic mines, and domestic self-developed products are not used much. High-pressure down-the-hole drilling rigs have already begun to be promoted.

- Shipment equipment: electric rake is mainly used in China. Most mines have already used underground trucks. Some mines use shovel inserting machines.

Types of Heavy Equipment Used in Mining

- Large excavator

- Down-the-hole drilling rig

- Roller drill

- Pre-installed

- Mining truck

- Explosive carrier

- Belt conveyor

- Ventilation car

Mode of transport

- Bulldozer

- Long-distance road transportation

- STMP mode of transport

- Off-highway semi-trailer getting on and off from the rear

- Off-highway semi-trailer getting on and off ahead

- Hot wheels dedicated to excavator transportation

- Heavy-duty crawler transport vehicle transports semi-mobile equipment

- Lightweight trailer

USA

Price

Since there are many different models of mining equipment, there is no clear price. However, compared to Chinese mining equipment, the prices of mining equipment manufacturers usa may be lower. But you also have to consider transportation costs and time issues.

Current status of mining equipments

- Open-pit mine

With the large-scale mining of open-pit mines, advanced mining equipment in the United States presents two biggest characteristics:

- Large-scale mining equipments:

In 1998, the cat797 327t mining truck was launched.

- Intelligentization of mining equipments:

Since the beginning of the 1990s, the United States has realized real-time monitoring of large-scale open-pit mine equipment on a single-board computer. In recent years, American Modular Mining Systems has developed automated control management with the help of global positioning systems and high-performance data communication networks.

- Underground mine

- Complete equipment and a high degree of mechanization:

Mining equipment manufacturers USA have all realized mechanized supporting operations, and each process has no manual operation and no heavy physical labor. Large-scale equipment, serialization, and standardization.

- Equipment is trackless, hydraulic, and highly automated:

In terms of automation, the United States has successfully introduced new technologies such as unmanned driving. In recent years, important progress has been made in the automation of mining equipment.

Types of Heavy Equipment Used in Mining

- Large Mining Trucks

- Hydraulic Mining Shovels

- Large Dozers

- Electric Rope Shovels

- Rotary Drill Rigs and Rock Drills

- Motor Graders

- Large Wheel Loaders

- Draglines

- Wheel Tractor Scrapers

- Underground Mining Loaders and Trucks

Mode of transport

Inland River Coastal Transport

Ocean transportation

SPMT shipping method

Conclusion

The current era is already an information age, in which informatization has four major characteristics, namely, intelligent, electronic, global, and non-group. There is still a gap between mining equipment manufacturers in china and mining equipment manufacturers USA. Opportunities and challenges coexist on the journey to a powerful country in mining machinery manufacturing. If we want to change the current status quo, we must learn from experience and solve several problems:

- Overcome the technical bottleneck of the development of mining equipment

Develop heavy-duty hydraulic rock drills to promote the development of hydraulic rock drilling technology

Develop heavy-duty hydraulic crawler chassis to speed up the development of full hydraulic cone drilling

Development of high-pressure down-the-hole impactor and drilling tools

Research and develop numerical control technology suitable for mining equipment

- Update the development concept of mining machinery products

Supporting globalization

Functional modularity

Control automation

Operational humanization

- Strengthen the training of mining machinery development talents 1. Overcome the technical bottleneck of mining equipment development

Develop heavy-duty hydraulic rock drills to promote the development of hydraulic rock drilling technology

Develop heavy-duty hydraulic crawler chassis to speed up the development of full hydraulic cone drilling

Development of high-pressure down-the-hole impactor and drilling tools

Research and develop numerical control technology suitable for mining equipment

- Update the development concept of mining machinery products

Supporting globalization

Functional modularity

Control automation

Operational humanization

- Strengthen the training of mining machinery development talents