Are you the miner hunting down the first mining activity? Before showing off your glamorous skills, it is better to know the mining process and yield. Trying every mining method isn’t a wise idea at all. Second, it is essential to know the type of ore bodies and then go on your first mining job.

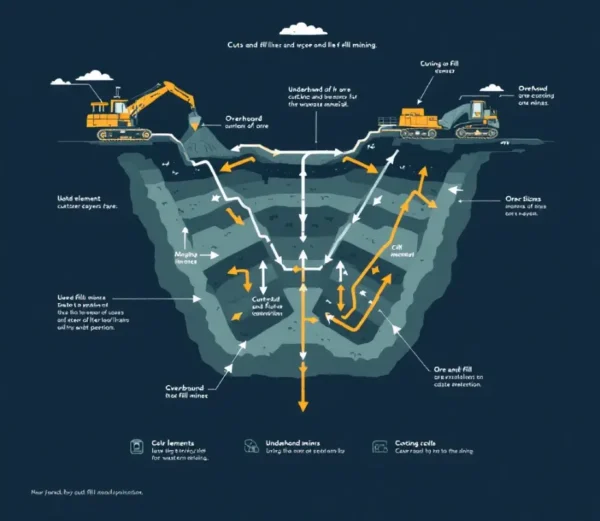

Nowadays many methods rely on the cutting and backfilling of the mine. One of the top methods is the cut-and-fill mining method.

Are you curious to know about this method? We will discuss this method in detail and understand the comprehensive structure of this mining method. Let us know.

What is a cut-and-fill mining method?

Cut and fill mining is one of the most prominent methods that is useful for deeper ore extraction.

The mining method relies more on the horizontal cutting of a specific area. Then, backfill that area with the waste materials. So, the filled area provides stability until the miners dig the next area.

The miners move from one area to another, repeating the process until they get all the precious items they have been looking for.

Step-by-step guide to excavating the ore bodies using cut and fill mining method

Cut and fill mining can be a more effective way to dig the steep ore bodies. It involves the horizontal cutting and filling of the excavated areas. Let’s discuss the various steps related to the cut-and-fill mining method.

Step 1: Determine Ownership

Understanding the ownership is of prime significance. It is because the owner will decide on the exploration method. Suppose the owner agrees with the cut-and-fill mining method.

Where will you get the machinery? How is the nearby environment? There is much more legal concern for the mining processes. So, you have to consider the ownership of the mining method.

Here is what you should focus on.

- The legal status of the land is essential for the digging.

- Some areas might need the necessary approval for the mining. As an owner, you must keep them in your bags.

- Coordination with the local authorities can save you from the hassles. All the authorities should be involved, and a local inspection of the areas should be conducted to ensure the mining’s suitability.

Step 2: Survey waste rock

Don’t prompt the digging process. It is better to survey the rocks and understand their suitability regarding the backfill. Also, the rock quality should be considered for the material assessment.

For the waste materials consideration, you can think of:

- Understand waste rock. Conduct surveys of various types. Take your experts to assess the rock.

- Identify hazards. Digging into the land can invite various unknown hazards. It is better to get prepared than to receive out-of-the-blue damages. Do the hazard calculations on time.

- Plan rock handling. After digging the rock, what will you do with that? Proper disposal and handling can ensure the safety of the environment. Have plans onboard to avoid the emergency hassles and planning.

Step 3: Assess backfill materials

Backfill material is the essential waste material that promises the stability of your land. Define how you will handle the backfilling. There are different types of backfilling on your way.

Consider them:

- Hydraulic backfill. Combine the waste material with the sand fill. This backfill provides excellent support for the next phase of mining. Moreover, it is suitable for almost all land mining operations.

- Pneumatic backfill. This backfill method involves pneumatic mixing of the rock and cement. It also creates an excellent stable surface for mining.

- Hydraulic rock backfill. Loose Rock Fill doesn’t offer much support. Moreover, it is suitable for the upper surface filling only. Technically, this method is not very famous for its backfilling method.

Whenever thinking about the backfilling, you have to:

- Assess the suitability of the backfill materials. For example, if the backfill is a waste material with rock and cement options, consider the local surface support.

- Always consider the backfill material’s strength, durability, and stability for the given surface.

Step 4: Hydraulic Fill Operations

Have you kept the above backfill operations in your hot-pick list?

Well. Hydraulic fill operations stand out as the best filling methods. It is because of:

- Excellent support from the material. Since the material is a mix of waste and rock, it has a better strength. It can sustain your mining equipment’s weight and provide a more stable surface.

- Best fit with mining equipment. One of the top reasons for making it a suitable match is its compatibility with hydraulic equipment. It lets the hydraulic tools move efficiently across the surface because of the stable surface.

Meet with the hydraulic fill operations. Mix the water with the hydraulic fill materials. This will make a paste. You can let this paste fill the excavated and empty surfaces inside the mining areas when you have excavated.

Step 5: Selection of access tools

Suppose you have reached the deeper areas of the land. Now, the ore is coming out. What is the ideal method you’ll try to use to access and dig the ore material?

It is none other than:

- Ramps. They provide easier access to the materials but provide lower-level access.

- Shafts. You can try them as ramp alternatives. But the shafts are more cost-effective solutions.

- Ladders. They can turn up as the best access for the ore and workers.

Step 6: Opt for quality equipment

Selecting the various equipment is crucial to performing every single mining phase. You can consider the following range of equipment.

- Heavy-duty excavation. Drills, loaders, and dump trucks are quite impactful tools for heavy-duty excavation.

- Excellent backfilling machinery. Mining a single portion of land isn’t necessary. Instead, backfilling is crucial to make it more weight-bearing and stable. So, select the top-notch backfill machinery.

- Assess and maintain your equipment. Consider the inspection and maintenance of all the tools you deploy for your backfilling or mining processes.

Step 7: Effective Ventilation

Miner’s safety is the hottest topic ever. Install the ventilation system to ensure it works smoothly and avoids suffocation.

Often, the raised areas are used for adequate ventilation. As an owner, you can further check the ventilation of the place and shake hands with the ventilation tools as well.

Try the ventilation fans and ducts. Maintain quality and ensure miners’ safety during operations.

Step 8: Proper mining of ores

The sketch of the mining process is quite evident with the guide out there. For the proper mining of the ores, you can understand the following steps.

- Mine the area. First of all, mine one specific piece of land. Extract all the materials you need for your work.

- Backfill. Choose the most suitable backfill material to fill the excavated place. Ensure it is stable and strengthened after the proper backfilling.

- Move to the next area. Let’s mine another piece of land ahead of the previous one.

Frequently asked questions

- Why is cut-and-fill mining used for steep or irregular ore bodies?

Cut and fill mining is famous for its compatibility with the steep ore bodies. It is because of the stable and controlled excavation with the required depths. Miners can effectively reach the steep surfaces without compromising the results and health safety.

- Which material is the best for the cut-and-fill mining method?

There are various types of materials. Only the integrity and surface stability materials stand out as the best material. In this case, you can consider hydraulic fill, which is a mixture of waste materials with rock particles. It creates an ideal paste that can fill the space and provide better stability on the ground surface.

- Is the cut-and-fill mining method risky?

Yes. It can be risky if you have a suitable backfill material ready for the stable surface. To ensure safety, you can prepare a quality backfill material that promises ground stability. Also, quality tools with protection could defy all the risks.

- What are the tools I need for the cut-and-fill mining method?

Cut and fill mining methods range from cutting to filling tools. Here is the comprehensive list of machinery required for this excavation method.

- Drilling Equipment

- Blasting Tools

- Loaders and Haul Trucks

- Conveyors and Pumps

- Backfill Mixers

- Hydraulic Fill Equipment

- Ventilation Fans and Ducts

- Access Ladders and Ramps

- Safety and Monitoring Devices

- Rock Bolters

- Ground Support Materials (mesh, shotcrete)

Conclusion

Mining and digging up the previous materials is quite essential for the consumers. But all that matters is the quality tools needed to dig deeper into the surface and enjoy the next-level stuff. Cut and fill mining stands out as the top method for better yield.

But do you have relevant underground digging tools? If not, don’t worry; Jinan Fucheng Hydraulic Equipment can be your stop for the premium tools for underground mining. Excavate the rough surfaces and fetch the precious metals. Talk to the experts to grab the quality tools right away!