Avez-vous déjà conduit votre voiture dans un tunnel ? Parfois, c'est la scène la plus incroyable lorsque vous êtes super excité. Le contraire se produit lorsque vous entendez parler de l'effondrement d'un tunnel.

Vous avez peut-être entendu parler de l'effondrement d'un tunnel. Mais la structure de fabrication des tunnels souterrains est si robuste qu'elle ne s'effondre pas.

Voulez-vous savoir pourquoi il ne s'effondre pas et quel est le processus exact de creusement d'un tunnel ? Si oui, ce guide est fait pour vous. Nous parlerons du processus de creusement des tunnels et vous ferons comprendre pourquoi il est extrêmement sûr.

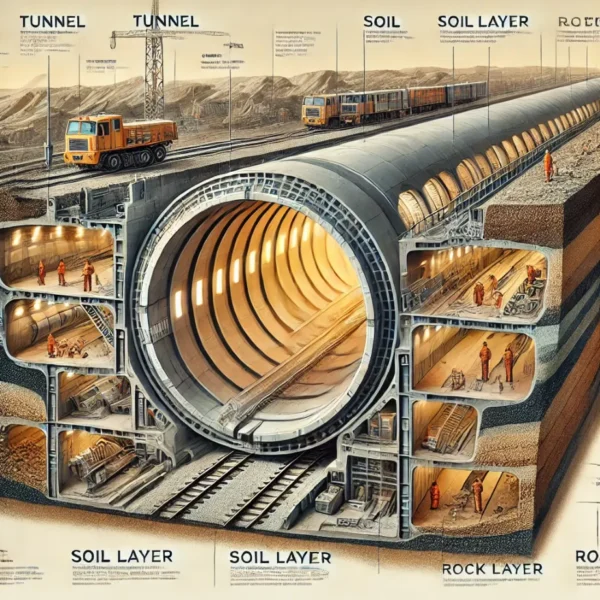

Qu'est-ce qu'un tunnel souterrain ?

Un tunnel souterrain traverse la roche ou la montagne avec seulement une entrée et une sortie. Il s'agit d'une sorte de grotte qui permet aux véhicules et aux objets de la traverser en toute sécurité.

En creusant la roche et en la renforçant de manière adéquate, on peut créer des tunnels et les rendre incassables.

Pourquoi un souterrain ne s'effondre-t-il pas ?

Des centaines de véhicules passent dans un seul tunnel. Pendant un instant, vous pouvez avoir peur : que se passe-t-il si votre tunnel s'effondre ?

La bonne nouvelle, c'est que vous n'avez pas à vous soucier des risques de résistance et d'effondrement. Il s'agit déjà d'un passage imbattable qui devient sûr au fur et à mesure :

Sélection minutieuse du lieu

Chaque endroit ne peut pas être idéal pour le tunnel. Tous les endroits robustes et adaptés au creusement de tunnels peuvent être transformés en tunnels souterrains. Cette sélection minutieuse permet d'éviter les dommages et les effondrements.

Une forme de tunnel appropriée

La forme du tunnel est telle qu'elle transfère la pression aux alentours. Au lieu de pressuriser les points faibles, une répartition égale assure un creusement correct du tunnel et une meilleure sécurité. Par conséquent, l'effondrement du tunnel n'est pas aussi facile qu'on pourrait le croire.

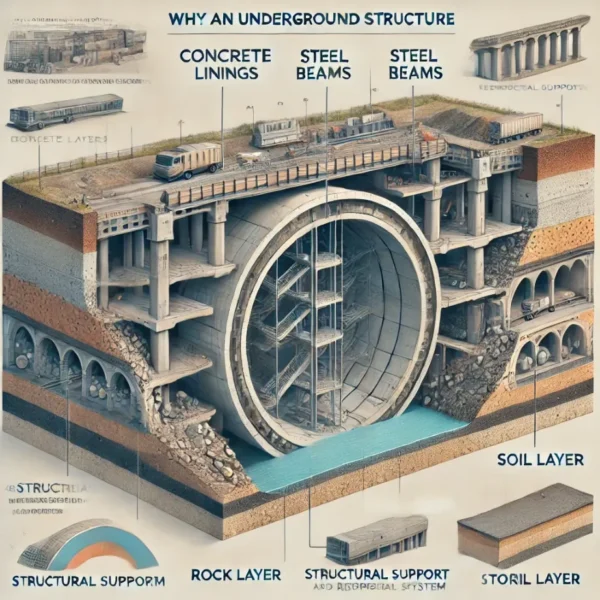

Renforcement

Les tunnels souterrains risquant de s'effondrer, ils sont accompagnés de renforts.

L'ajout des matériaux de renforcement suivants fait du tunnel un espace parfait.

- Béton projeté

- Nervures en acier

- Boulons de roche

Techniques avancées et surveillance

De nos jours, vous avez accès à une technologie de pointe pour le creusement des tunnels. De plus, des inspections régulières peuvent vous éviter des effondrements. La détection des dommages et des fissures a réduit les risques d'effondrement et fourni une plate-forme parfaite pour la construction des tunnels.

Les tunneliers sont un choix exceptionnel pour vos tunnels et sont d'une excellente résistance. Des essais appropriés et l'adéquation sont des facteurs de sécurité.

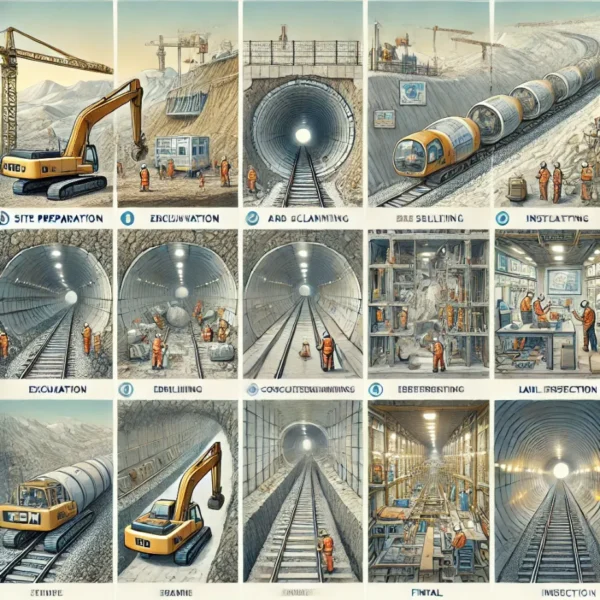

Etapes de la construction d'un tunnel souterrain

La construction d'un tunnel souterrain n'est rien de moins qu'une merveille. Créer une structure robuste qui ne cède pas est une idée tout à fait fantastique. Mais ne vous inquiétez pas ! Les plans et les stratégies appropriés sont là pour vous aider à créer un tunnel parfait qui restera en place pendant plusieurs décennies, voire plusieurs siècles.

Suivez les étapes ci-dessous pour comprendre comment le tunnel souterrain peut vous aider.

Étape 1 : Planification initiale et étude de faisabilité

Tous les sites ne sont pas idéaux pour le creusement de tunnels souterrains. Une évaluation et une planification précoces peuvent éviter des problèmes futurs et garantir l'exécution exacte des résultats.

Il y a beaucoup plus à cibler dans la planification initiale.

- Examen des types de roches avec le sol. Détermination de l'aptitude du sol au creusement et à la création de tunnels.

- Pourquoi créez-vous le tunnel ? Il est essentiel de définir les buts et les objectifs du tunnel souterrain.

- La localisation de l'environnement proche permet de définir ses impacts. Il faut donc penser aux impacts environnementaux en fonction des conditions locales.

- Quel est le budget ? Quelle est la durée du projet de creusement de tunnel ?

Étape 2 : Conception et ingénierie

Il faut garder en mémoire le plan du tunnel. Un travail d'ingénierie exemplaire n'est possible que si l'on dispose des diagrammes et des organigrammes.

En tant que maître d'ouvrage et planificateur, vous pouvez opter pour les concepts et idées suivants lors du creusement d'un tunnel.

- Quel est le tracé optimal pour le creusement d'un tunnel ? Vérifiez tous les aspects sur la base des études structurelles et géologiques.

- Comprendre et définir la forme du tunnel. Déterminez si elle est circulaire, en fer à cheval ou rectangulaire.

- Avez-vous prévu une ventilation et un drainage de l'eau de pluie ? Pour obtenir les résultats escomptés, tous ces facteurs doivent être réunis dans un tunnel adéquat.

Étape 3 : Choix de la méthode d'excavation

L'une des tâches les plus difficiles consiste à gérer l'excavation et à trouver la méthode de sélection. Il existe différents types de méthodes d'excavation pour le creusement de tunnels.

Envisager :

- Forer et dynamiter. Y a-t-il une roche dure à l'endroit où vous envisagez de créer le tunnel ? Il existe des méthodes folles et explosives telles que le forage et l'abattage à l'explosif. Ils dynamitent et créent l'espace nécessaire au creusement du tunnel.

- Méthode de creusement des tunnels. Vous avez un long tunnel à créer ? La méthode fastidieuse du creusement de tunnel est le choix idéal dans ce cas.

- Couper et couvrir. C'est une excellente méthode. Les ouvriers créent d'abord le tunnel et le recouvrent ensuite.

- Pose d'un tuyau. Pour les petits tunnels, le fonçage de tuyaux est la technique préférée de tous.

Étape 4 : Préparation du site

La préparation du site comprend les installations nécessaires. Par exemple, vous creusez un tunnel dans un endroit éloigné. Comment allez-vous alimenter les machines et les faire fonctionner ? Obtenez l'électricité ou déployez des générateurs.

Il y a beaucoup plus à préparer dans ce cas. Il s'agit notamment de

- Tunnels d'accès. La construction d'un puits est une idée unique pour accéder aux tunnels. Elle permet un accès instantané et donne des résultats extraordinaires dans le processus de creusement des tunnels.

- Système de services publics. Quel est votre plan pour faire payer vos travailleurs ? Déployez des systèmes d'eau et des matériaux alimentaires pour leur énergie.

- Mesures de sécurité. Le creusement d'un tunnel exige des efforts extraordinaires. Le fait de pénétrer profondément dans le tunnel peut être dangereux pour les travailleurs. Pour leur sécurité, ajoutez des barrières ou aménagez des sorties de secours.

Étape 5 : Excavation et appui au sol

Il est temps de faire de véritables efforts. En utilisant votre méthode préférée, vous pouvez commencer à construire le premier tunnel. Creusez la roche et extrayez les matériaux.

Vérifier le soutien du sol et installer les murs pour en assurer la stabilité. Créer un mécanisme approprié pour l'élimination des roches et des déchets de la surface.

Que faire pour soutenir les murs et le sol ? Injecter du ciment. Ou ajoutez les produits chimiques. Ils rendront les murs impénétrables et faciliteront le creusement des tunnels et la production de fruits.

Étape 6 : Doublage et imperméabilisation

Le revêtement et l'étanchéité sont des phénomènes extraordinaires. Il faut penser à toutes les possibilités pour renforcer les parois des tunnels.

Voici ce qu'il faut savoir.

- Doublure primaire. Tout d'abord, il faut créer le premier revêtement. Il doit être renforcé par des matériaux tels que le béton projeté et les arcs en acier.

- Membrane d'étanchéité. Ajoutez l'eau qui s'infiltre car elle peut endommager le mur et compromettre sa sécurité. Pour cela, vous pouvez installer une membrane qui ne laisse pas passer l'eau.

- Doublure finale. Réalisez maintenant le revêtement final. Construisez-le avec le ciment pour assurer l'intégrité structurelle et le soutien du sol.

Étape 7 : Installations mécaniques et électriques

Une fois que vous avez creusé et créé une parcelle de tunnel, optez pour le tunnel long en fonction de vos besoins.

Vous devez prendre en considération

- Le système de ventilation apporte un soutien extraordinaire. Vous pouvez vérifier la qualité de l'air et installer des nettoyeurs pour ce système.

- Système d'éclairage. Pour illuminer l'ensemble de la scène, procurez-vous un système d'éclairage de qualité. Veillez à ce qu'il ne nécessite pas beaucoup d'entretien ; sinon, vous vous retrouverez coincé dans l'entretien de vos systèmes d'éclairage.

- Lignes de services publics. Installer de nombreux outils utilitaires. Par exemple, des câbles et des tuyaux peuvent être déployés. Connaître l'étendue et la faisabilité de ces systèmes.

Étape 8 : Inspection finale et suivi

Vous souhaitez évaluer la qualité des tunnels que vous avez créés ? Pour cela, vous pouvez déterminer les aspects suivants.

- Surveillance géotechnique. Venez avec les capteurs pour surveiller l'activité du sol. Y a-t-il des risques d'effondrement ? Atténuez-les immédiatement en adoptant la bonne approche.

- Essais. Effectuer des tests mécaniques et structurels. S'il y a un problème ou un risque d'effondrement, mentionnez-le. Inspectez également le tunnel pendant des périodes prolongées afin de détecter d'éventuelles fissures ou dommages.

- Inspection régulière. N'oubliez pas d'apporter la touche finale aux tunnels. Inspectez-les régulièrement et mettez-les à jour s'ils présentent des signes d'usure ou de détérioration. Traitez-les immédiatement pour éviter tout incident futur.

FAQ

- À quoi sert un tunnel souterrain ?

Le creusement de tunnels souterrains répond à de nombreux objectifs. Il peut s'agir de

- Formes d'exploitation des minerais et maximisation de l'efficacité de l'exploitation minière

- Création d'allées et de routes à travers les zones.

- Quels sont les types de tunnels souterrains les plus courants ?

Il existe différents types de tunnels souterrains. Cependant, nous avons levé le voile sur les trois principaux.

La liste comprend

- Coupe et couverture

- L'ennui

- Immergé

Ce sont les plus célèbres d'entre eux qui sont utilisés dans l'industrie et qui sont constamment loués pour leurs performances de haut niveau et leurs expériences de sécurité ultimes.

- Qu'est-ce que la dérive du pilote ?

La galerie pilote est un petit tunnel utilisé pour l'excavation et l'inspection. Cette galerie se trouve au-dessus des grandes galeries et joue un rôle crucial dans l'évaluation.

Conclusion

Le creusement de tunnels souterrains nécessite une machinerie importante qui doit être de qualité. En outre, les techniques doivent présenter des failles. Dans le cas contraire, les mineurs risquent de s'effondrer après quelques périodes. Cela compromettrait également la sécurité des personnes.

Vous souhaitez disposer de la meilleure configuration de machines pour votre processus de creusement de tunnels souterrains ? Faites confiance à Équipement hydraulique de Jinan Fucheng qui est compatible avec tous les types de tunnels souterrains et qui présente la plus grande efficacité sur le site. Découvrez les conceptions de qualité et les prix proposés par les experts dès maintenant !