Introduction

LHD machine is a load haul dump machine. It is mainly used in underground mines and tunnel projects. The tires of the LHD scoop adopt smooth or semi-glossy durable cutting engineering. And the load haul dump machine has a diesel engine exhaust purification device.

Classification of LHD Machine

According to power source

According to the power source, it can be divided into internal combustion scrapers powered by diesel engines and electric scrapers powered by electric motors. The following are the advantages and disadvantages of the two LHD machines:

Internal combustion LHD machine

Electric LHD machine

According to bucket capacity

Small LHD machine: LHD scoop with a bucket capacity of 1.5m³ and below.

Medium LHD machine: LHD scoop with a bucket capacity of 2-4m³.

Large LHD machine: LHD scoop with a bucket capacity of 4m³ and above.

Working device of LHD Machine

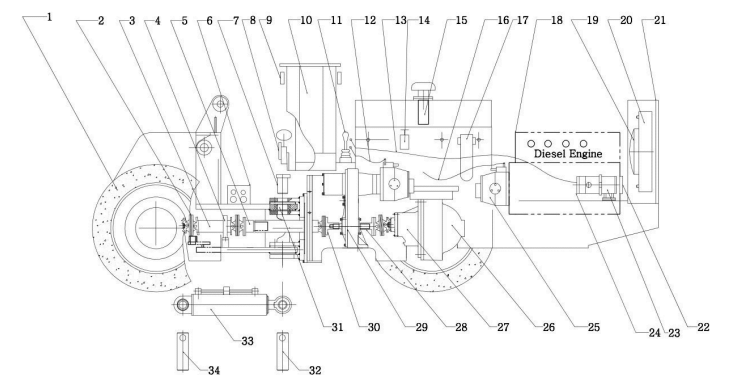

Scraper working device sketch

1-tyre 2-drive shaft1 3-drive shaft2 4-bridge bearing 5-drive shaft3 6-multi-directional control valve

7-central pin shaft 8-diverter 9-front and rear light 10-driver cab 11-pilot valve 12-soft shaft of mot

13-soft shaft of the engine 14-over-flow valve 15-filter 16-soft shaft for traveling 17-filter assembly

18-Diesel engine 19-DC Fan 20-rear caudal frame 21-rear caudal frame 22-belt wheel 23-pump seat

24-main pump 25-traveling pump 26-driving axle 27-main differential 28-shaft fork1 29-transfer case

30-shaft fork2 31-articulate bearing 32-rear steering pin 33-Steering cylinder 34-front steering pin

The working principle and process of LHD machine

The Underground LHD machine can load, transport, and unload. It is self-propelled equipment. The working process of the LHD machine in mining can be reflected on the working device. The length of the lifting cylinder and the rotating bucket cylinder determines the various working conditions of the working device. Its working process consists of 5 working conditions:

- Insertion conditions:

The boom is lowered, the bucket is placed on the ground, the tip of the bucket touches the ground, the bottom of the bucket is at an angle of 3°-50° with the ground, and the bucket is inserted into the pile by the traction of the machine.

- Shovel loading conditions:

After the bucket is inserted into the material pile, turn the bucket to shovel the material until the bucket mouth is turned to approximately level.

- Lifting conditions:

After the bucket is retracted, use the lifting cylinder to rotate the boom to the proper unloading position.

- Unloading conditions:

Use the bucket cylinder to turn the bucket over and unload it to the transport vehicle. Then lower the boom to restore the bucket to the transport position.

- Automatic leveling conditions:

After the bucket is unloaded at the highest lifting position at 45°, keep the length of the bucket cylinder unchanged. When the boom is placed in the digging position, the rear angle between the bottom of the bucket and the ground plane is 300-500.

The origin of the transmission system

Requirements for vehicle driving:

- Speed range of normal driving: 6-10 times

- The range of traction: 10-15 times

- Able to reverse

- Can cut off power

- Can brake quickly

- Able to correct or change direction

Insufficiency of power plant performance:

- The speed range is not wide, the maximum speed is about 1.5-2.75 times of the minimum speed

- Narrow torque range

- Can not rotate in both directions (reverse)

- Can not output power at low speed, that is, can not start with load

Underground LHD machine transmission scheme

Underground load haul dumper machine usually adopts a hydraulic mechanical transmission system. For Underground LHD machine: Bucket capacity> 1m³, using hydraulic mechanical transmission system; Bucket capacity <1m³, using hydraulic mechanical transmission system or hydrostatic transmission system.

Hydro-mechanical transmission system

Advantages: It can make full use of the power machine, and automatically adapt to changes in external resistance within a certain range, and carry out step-less speed regulation. When the external resistance suddenly increases, overload of the power machine and damage to the machine parts can be avoided. Smooth operation and reliable work. Disadvantages: extremely low transmission efficiency, complex structure, high manufacturing and maintenance costs.

Hydrostatic transmission system

- The high-speed solution uses high-speed hydraulic motors and mechanical transmission, that is, a hydraulic-mechanical transmission system.

- The low-speed scheme is driven by a low-speed hydraulic motor by the wheel, that is, a full hydraulic transmission system.

Main components of LHD machine

Torque converter

The role of the torque converter

The torque suitability coefficient of the diesel engine is small. Therefore, it cannot meet the requirements of frequent overloading and frequent changes in a load of underground vehicles. In order to solve this problem, a hydraulic torque converter is added behind the diesel engine. The advantages and disadvantages of adding torque converter compared with mechanical transmission: Advantages: make the vehicle have automatic adaptability. Improve the service life, passing performance, and comfort of the vehicle. Simplify the operation of the vehicle. Disadvantages: high cost. The torque converter itself has low efficiency and high maintenance and manufacturing costs.

The parameter test of the torque converter

- The normal pressure of the torque converter is 1.69-1.96Mpa, and the deviation cannot exceed 0.04Mpa.

- The maximum oil temperature cannot exceed 121°C. The normal working oil temperature is 82.2℃-93.3℃.

- The test method of the highest oil temperature: put in third gear and step on the brake. When the car is not moving, the engine speed is controlled at 1500rpm, and the torque converter oil temperature does not exceed 121°C after 25 minutes of operation.

Gearbox

The role of the gearbox

- Change the transmission ratio between the power machine and the main drive wheels, thereby changing the traction and driving speed of the vehicle.

- Drive the vehicle backwards.

- When the gearbox is in neutral, the power from the power machine to the drive wheels is cut off so that the power machine can be started. Or when the power machine is running, the vehicle can be stopped for a longer period of time.

- The speed change is twisted.

The classification of gearboxes

Planetary gear transmission

Fixed axis gear transmission

Drive Shaft

The role of the drive shaft

- Increase the torque transmitted from the engine.

- The left and right driving wheels have different torques, and the two wheels have a differential function.

- Withstand various forces from the road surface and the frame.

The structure of the drive shaft

- Main drive: large carrying capacity and high efficiency.

- Differential: divided into ordinary differential and anti-skid differential.

- Wheel reducer: The planetary reduction structure can further increase the output torque.

- Brake: Fully enclosed hydraulic wet multi-disc brake. Stable and reliable, adapt to harsh working environment.

Transmission shaft

- The role of the drive shaft: mainly connects non-concentric axis, or power transmission between two parts with position changes.

- The drive shaft is also called universal transmission. It includes universal joints, drive shafts and intermediate brackets.

- Universal joint: There are two kinds of elasticity and rigidity.

Conclusion

With the continuous update of technology, the mining industry no longer emphasizes the problem of large-scale development of LHD machines. Instead, they focused on the improvement of equipment performance and reliability. There are many well-known LHD machine manufacturers in the world. This article mainly introduces the structure and working principle of the LHD machine. You can also choose your favorite LHD machine in mining in Fucheng.